Fuji Electric Co., Ltd. is pleased to announce the launch of the P641 Series 3rd-generation small IPM, which helps reduce the power consumption of air conditioners and other home appliances.

1. Background

As countries around the world set energy saving targets toward decarbonization, it is also necessary to reduce the power consumption of home appliances in the market. Air conditioners specifically account for most of the electricity consumed by typical households, so improving their power consumption efficiency will contribute significantly to energy saving.

Fuji Electric’s Intelligent Power Modules (IPMs) are high-performance power semiconductor devices equipped with a built-in IGBT drive circuit and protection function. They control the rotational speed of compressors by controlling the voltage and frequency by switching (turning electricity on and off) mainly in the inverter circuit of air conditioner outdoor units. This allows the air conditioners to maintain the room temperature optimally.

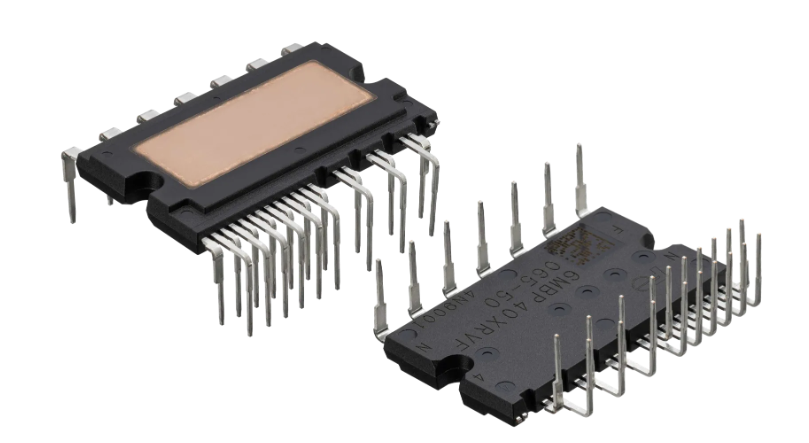

This P641 Series 3rd-generation small IPM uses FE’s latest-generation power semiconductor chip to enhance conductivity and achieve miniaturization while reducing power loss by 10% compared with conventional products. It contributes to reducing the power consumption and space footprint of the equipment in which it is used.

3rd-generation small IPM P641 Series

2. Features

1) 10% lower power loss and 44% smaller footprint

This product integrates FE’s latest 7th-generation RC-IGBT*1 chip. The resistance of the current path (drift layer) has been reduced by making the chip thinner and optimizing the withstand voltage structure. In addition, the surface structure of the chip has been miniaturized and the current paths arranged in high density to reduce conduction loss.2 This has led to an approximately 10% reduction in power loss compared to FE’s conventional product (P633 Series). Further, increasing the output per unit area has allowed the product footprint to be reduced by 44% compared to the conventional product, contributing to the miniaturization of inverter circuits.

*1: Reverse-conducting insulated-gate bipolar transistor

*2: Loss caused by resistance during current flow

2) Achieving the same heat dissipation as conventional products to make the industry’s first series of 40 A-rated products

In general, the smaller a semiconductor, the lower its heat dissipation. Therefore, this series uses resin insulating sheets with high heat dissipation to reduce thermal resistance by 25% and achieve the same heat dissipation performance as conventional products. The internal layout of the product has also been optimized to accommodate larger chips. This has allowed the company to achieve the first series in the industry to cover current ratings of up to 40 A in products with the same external dimensions.

3. Product Specifications

| Model | Rated voltage | rated current | Self-stopping overheat protection | Package size |

| 6MBP20XRVF065-50 | 650V | 20A | Integrated | (W)18.8mm ×(D)32.8mm ×(H)3.6mm |

| 6MBP30XRVF065-50 | 30A | |||

| 6MBP40XRVF065-50 | 40A |

4. Launch Schedule

As of the date of this announcement.

Note: Information contained within this news release is as of the time of release and is subject to change without prior notification.